- Home

- Products

- Headlight Assembly Machine

- Headlight Bulb Alignment Machine

- H1 Headlight Bulb Alignment Machine, Adjusting Focus and Installing

H1 Headlight Bulb Alignment Machine

The H1 headlight bulb alignment machine is available with two different pre-focus bases: a laser beam welder and a resistance welder. It is designed to complete capping and focus adjustment during headlight assembly. Once each halogen capsule bulb and lamp holder is assembled, a lighting test is conducted to ensure any bulbs that fail to light will not enter the lamp holder installation process. In doing so, we guarantee the reliable, high quality performance of each headlight installed in the holder.

| Device Name | H1 Headlight Bulb Alignment Machine (with resistance welder for welding pins and laser beam welder for prefocus base) | |

| Model | AF-DJ-H1-JG | |

| Power | Main Engine Drive | 2 x 1 Kw/pcs |

| Resistance welder | 10 X 2 kw/pcs | |

| Laser beam welder | 18 x 1 kw/pcs | |

| Pressure | 0.6 Mpa | |

| Production of the beat | 1200-1440pcs/h | |

| Dimension(W×D×H) | 1900mm×1900mm×2000mm | |

| Device Name | H1 Headlight Bulb Alignment Machine (with resistance welder for welding pins and laser beam welder for prefocus base) | |

| Model | AF-DJ-H1-DZ | |

| Power | Main Engine Drive | 2 x 1 Kw/pcs |

| Resistance welder | 10 X 4 kw/pcs | |

| Pressure | 0.6 Mpa | |

| Production of the beat | 1200-1440pcs/h | |

| Dimension(W×D×H) | 1300mm×1000mm×1500mm | |

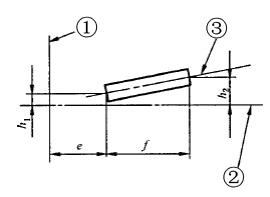

The h1 values in horizontal and vertical directions are measured separately. The drive mechanism moves the filament to the reference axis.

- Reference plane

- Reference axis

- Filament axis

Foshan Focus Automation Equipment Co., Ltd.

Add.: A1, No.33, First Industrial Zone, Xiebian, Dali Town, Nanhai District, Foshan City, Guangdong Province

Contact: Li Wei (Mr.)

Tel: +86-757-81036610

Fax: +86-757-81036610