- Home

- Products

- Headlight Assembly Line

- Headlight Assembly Line for H1 Halogen Bulb

Headlight Assembly Line for H1 Halogen Bulb

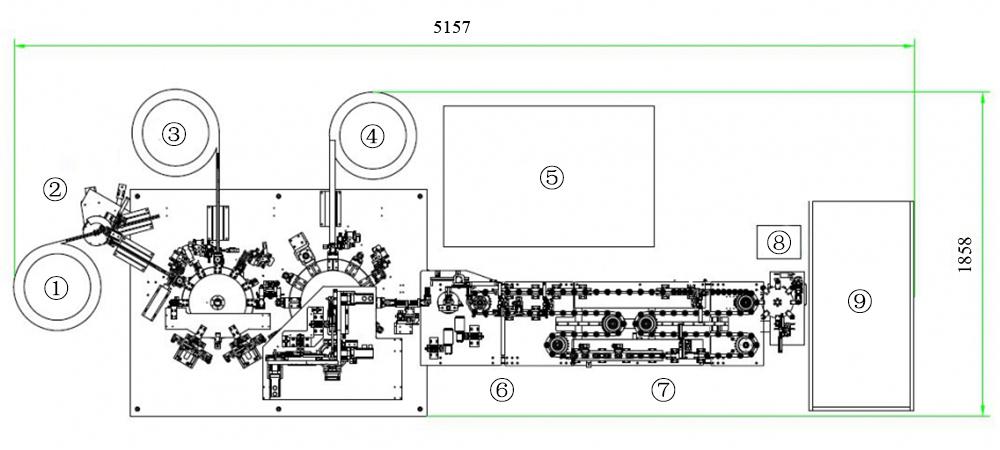

The headlight assembly line for H1 halogen bulbs is designed to assemble halogen capsule bulbs, bulb holders, and prefocus bases in the production process of H1 halogen bulbs. The line offers excellent automation that only requires one operator. It is composed of a H1 headlight bulb alignment machine, welder, headlight bulb specification data inspecting machine, and marking machine. The H1 headlight bulb alignment machine has a compact structure, capable of the assembling of halogen and bulb holder, focus adjusting and welding. The headlight bulb specification data inspecting machine and laser beam marking machine can be chosen based on customer demands. Headlight bulb specification data inspecting machine can complete the measurement of h1, h2, e, f and g headlights and the additional functions of cold resistance and power tests. H1 halogen bulbs produced by the headlight assembly line with headlight bulb specification data inspecting machine meet ECE regulations. The laser marker can be set automatically for the printing of headlight models, company logos and other parameters.

Before feeding the halogen capsule bulb, the halogen capsule bulb will undergo a lighting test, and the damaged halogen capsule bulbs will be automatically removed to avoid wasting the bulb holder. The visual system is applied to inspect the direction of the halogen capsule. If it is reverse, the manipulator is controlled to correct the halogen capsule bulb.

Required operator: 1 operator

Size: 5157X1858mm

- Halogen capsule

- Halogen capsule leak inspection turntable

- Light bulb head

- Prefocus base

- Laser beam welder

- Headlight Bulb Specification Data Inspecting Machine

- Flexible chain

- Laser marker

- Inspecting bench

The FsFocus headlight bulb alignment machine features a compact design and delivers high production efficiency. Equipped with our self-developed visual adjusting focus system and German Baumer high-definition camera, the pixel count is high and the focus accuracy is excellent. Additionally, each bulb will undergo lighting tests before feeding the halogen capsule. This ensure that unqualified halogen capsules will not be placed in the lamp holder installation process.

Parameters

| Device Name | H1 Headlight Bulb Alignment Machine (Resistance welder for welding pins and laser beam welder for prefocus base) | |

| Model | AF-DJ-H1-JG | |

| Power | Main Engine Drive | 2 x 1 Kw/pcs |

| Resistance welder | 10 X 2 kw/pcs | |

| Laser beam welder | 18 x 1 kw/pcs | |

| Pressure | 0.6 Mpa | |

| Production capacity | 1200-1440pcs/h | |

| Dimension (W×D×H) | 1900cm×1900cm×2000cm | |

In the assembly of headlights, deformation may appear in the welding process after adjusting focus. Then we can add this headlight bulb specification data inspecting machine for the headlight assembly line to inspect the focusing conditions. Headlight bulb specification data inspecting machine for H1 halogen bulb can inspect the values of h1, h2, e, f and g of H1 headlights to ensure focusing accuracy.

Parameters

| Device Name | H1 Headlight Bulb Specification Data Inspecting Machine |

| Model | AF-FG012-H1 |

| Power | 0.5x 1 Kw/pcs |

| Pressure | 0.65Mpa |

| Production capacity | 1200-1440pcs/h |

| Dimension (W×D×H) | 300cm×300cm |

-

High end halogen production line

Introduction

The high end headlight assembly line for H1 halogen bulbs is equipped with a headlight bulb specification data inspecting machine, laser marker and inspecting bench. After assembling the whole H1 headlight, the headlight bulb specification data inspecting machine will inspect the focusing size of the headlight, and measure the cold resistance, power, etc. This makes sure that each produced headlight meets E.C.E. standards.Configuration

H1 Headlight Bulb Alignment Machine ( Laser beam welder), Headlight Bulb Specification Data Inspecting Machine, Resistance tester, Power tester, Laser marker, Inspecting bench -

Economic vehicle headlamps production line

Introduction

The economic headlight assembly line for H1 halogen bulb features simple structure and practicability.Configuration

H1 Headlight Bulb Alignment Machine (equipped with a resistance welder)

Foshan Focus Automation Equipment Co., Ltd.

Add.: A1, No.33, First Industrial Zone, Xiebian, Dali Town, Nanhai District, Foshan City, Guangdong Province

Contact: Li Wei (Mr.)

Tel: +86-757-81036610

Fax: +86-757-81036610